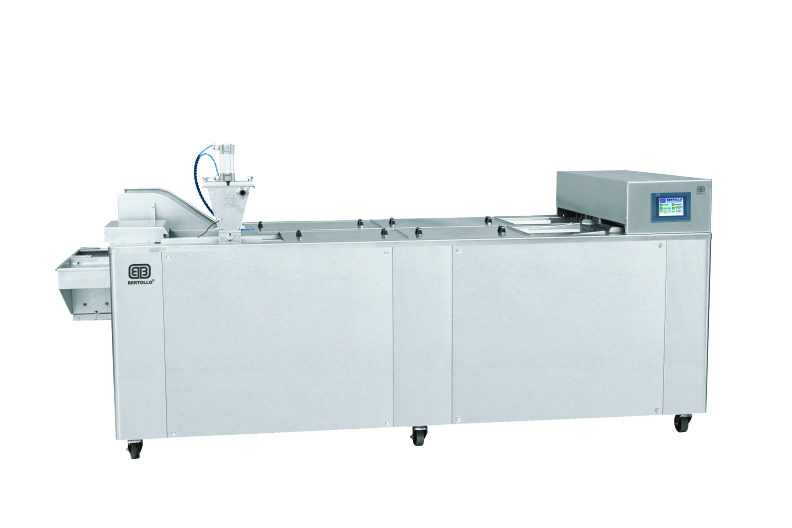

Popsicle Producer

Industrial Use

The BERTOLLO pickpockets of the "comes and goes" line represent the application of the most modern concepts of thermal efficiency. Its design provides the optimization of the physical space it occupies, with the maximization of thermodynamic efficiency and the production process.

Cooling tank made of 304 stainless steel, thermally insulated with expanded polyurethane, uses ethyl alcohol as a coolant. The fluid completely fills the entire tank and remains in constant contact with all shapes and the copper coil, the thermal balance is guaranteed by the action of mechanical stirrers manufactured in stainless steel 304, with sealing by mechanical seal.

The movement of the forms takes place through a set of pneumatic actuators, with fully automated control. At the end of the popsicles freezing process, the molds are suspended on a ramp for the exit and recovery of the alcohol.

They are equipped with deformer for formwork.

The agitators, deformer, pneumatic actuators and cooling system are controlled by a programmable logic controller, PLC, type “TouchScreen”, with optical safety sensor.

The refrigeration system is formed by a semi-hermetic compressor, refrigerant gas HP-81, water-condensed.

With the experience of over 30 years in the construction of ice cream machines, BERTOLLO uses in the manufacture of its equipment a water condenser, Shell and Tube type, designed and manufactured by BERTOLLO itself.

They can also be supplied with syrup dispenser and filling dispenser as options.

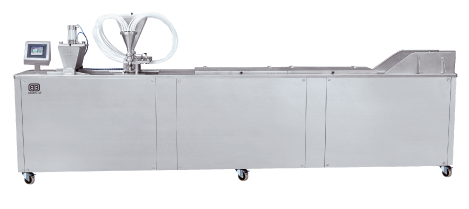

Industrial Use

Base with swivel casters with brake, structure and coatings in stainless steel 304.

Cooling tank made of 304 stainless steel, thermally insulated with expanded polyurethane, uses ethyl alcohol as coolant.

The fluid completely fills the tank and remains constantly in contact with all the forms and the copper coil, the thermal balance is guaranteed by the action of mechanical agitators manufactured in 304 stainless steel with mechanical seal.

At the end of the freezing process, the molds are suspended in a ramp for alcohol exit and recovery.

The agitators, pneumatic actuator or electric conveyor, pump and refrigeration system are controlled by a programmable logic controller, PLC, TouchScreen type, with optical safety sensor.

The refrigeration system is formed by a semi-hermetic compressor, HP-81 refrigerant gas, water condensation.

With over 30 years of experience in the construction of ice cream machines, BERTOLLO uses a water condenser, Shell and Tube type, designed and manufactured by BERTOLLO.

The Bertollo Picoleteers can be supplied, optionally, with a popsicle machine, already integrated in the machine by the factory itself. They can also be supplied with syrup dispenser and filling dispenser as optional, in which case the machine can integrate them at any time.